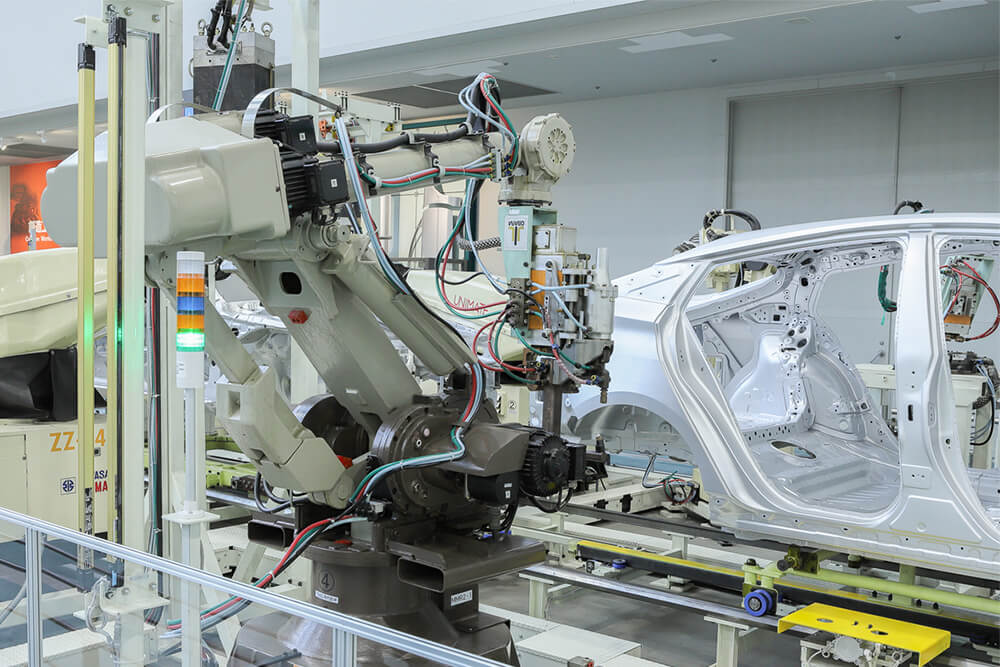

Body Welding in the Second Half of 1980s: High-Variation Manufacturing Meets Customer Needs

In the latter half of the 1980s, the growth of vehicle production slowed while consumer needs diversified. Toyota’s answer to the varying needs of customers was an innovative welding line introduced in 1985, called the Flexible Body Line. By integrating the process control from stamping to welding, the line supported just-in-time production of any model in any volume. The welding robots were developed in-house and placed at short intervals along the line, enabling high production efficiency even in high-variation manufacturing. At the same time, continuing increases in Japanese automobile exports exacerbated trade frictions with the U.S., which pressured Toyota into contemplating production abroad. This meant the company needed to redesign its welding lines to meet local production requirements.